Table of Contents

When the off-road community began fitting 43" tires and 600+ hp powertrains to their rigs, many found their factory and modified axles simply couldn’t keep up. Bored-out 35-spline spindles bent under shock loads, ball-joint C-ends wore prematurely, and exotic two-piece 40-spline conversions proved expensive and hard to service. Enter the KP540, a from-the-ground-up 40-spline, kingpin-style front axle system designed to handle modern off-road demands—without exotic pricing or proprietary wear parts.

Why Traditional Front Axles No Longer Cut It

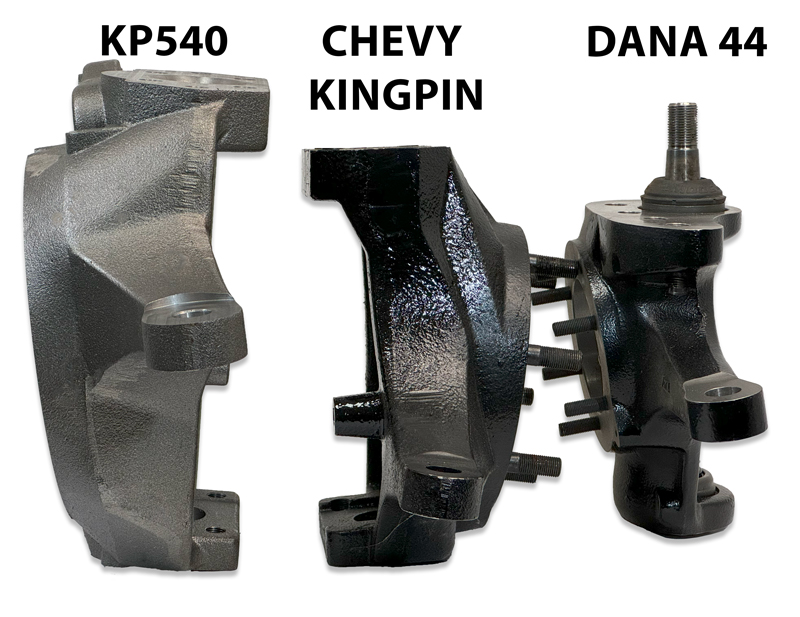

For decades, Dana 44s (2.5" OD tube, ¼" wall) and Dana 60s (3.125" OD, 7⁄16" wall) served as the gold standard for Jeeps, Broncos, and Buggies. But as builds grew more extreme—bigger tires, heavier rigs, higher horsepower—enthusiasts discovered three key limitations:

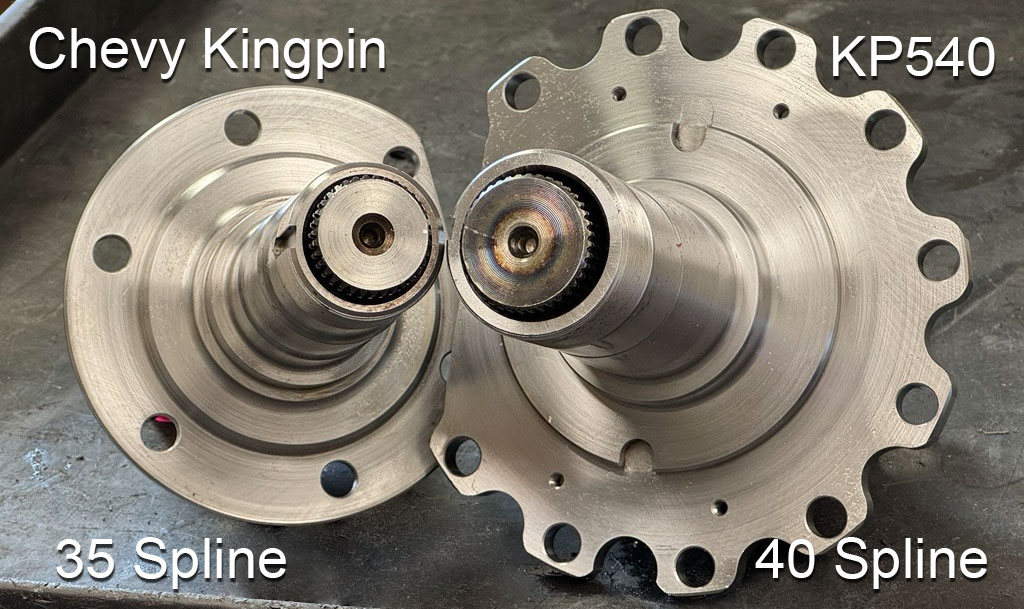

- Structural Weakness: As off-roading became more extreme, 35 spline axle began breaking under load. When 40 spline shafts entered the market, there wasn't a full wheel end solution to match. DIYers adapted by boring a 35-spline spindle to fit a 40-spline shaft which thins wall thickness, making it prone to bending under impact.

- Service Complexity: Unit-bearing / ball joint axles are quick to install at the manufacturer, but once worn or damaged, they require complete unit bearing and/or ball joint replacement—which can be more costly to repair, requiring special tools. Additionally, when outer stub shafts break, they often sheer the balljoint studs so balljoints aren't ideal for heavy off-road use.

- Cost Barriers: Fully engineered 40-spline solutions on the market tend to use two-piece shafts or exotic alloys in low volumes, pushing price tags into the thousands.

The Birth of the KP540

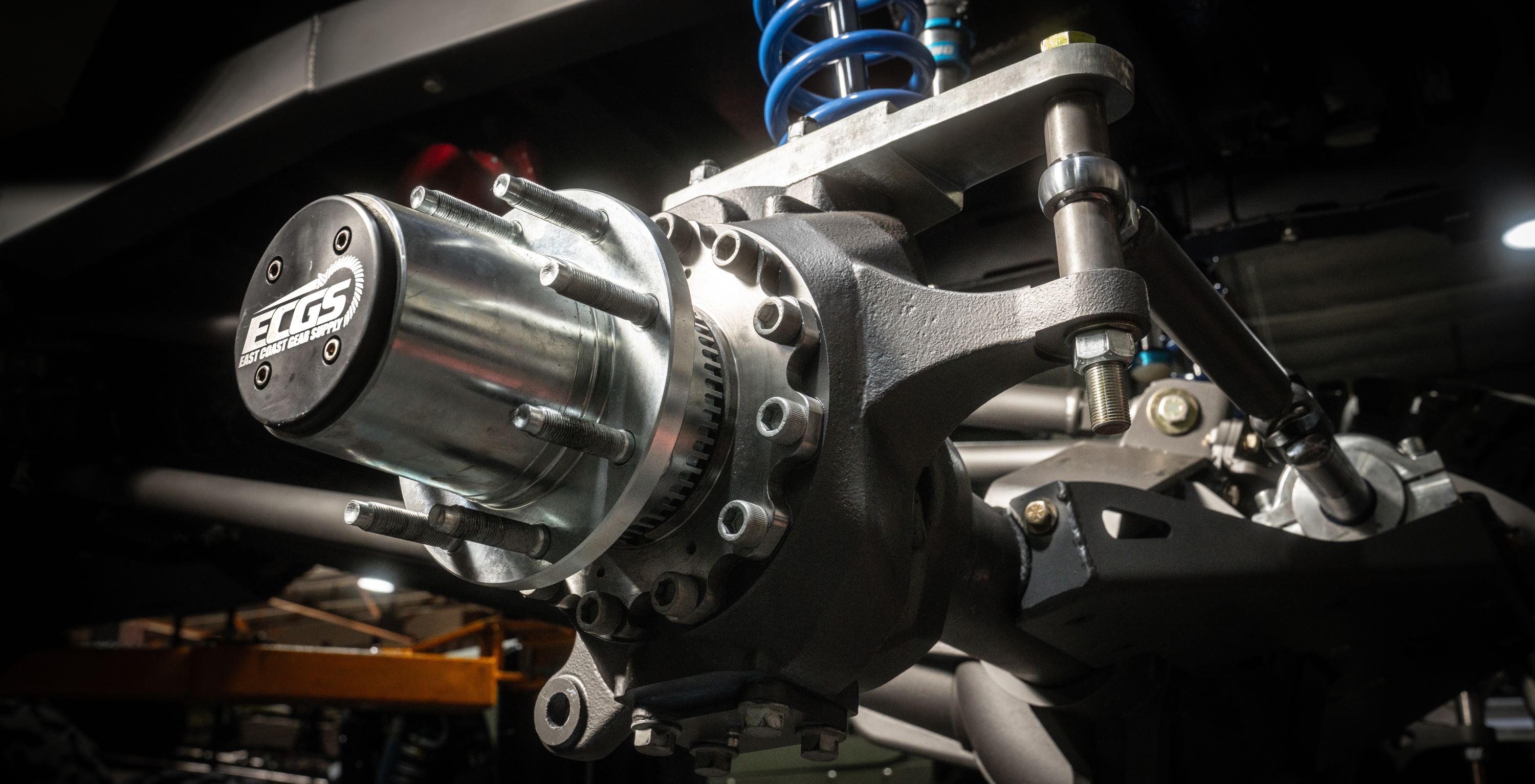

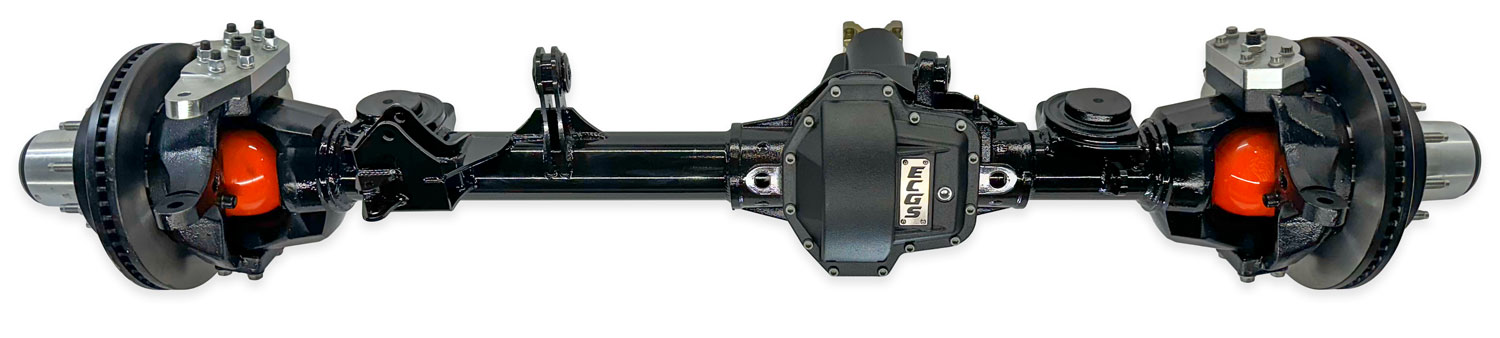

Chase Perry, founder of East Coast Gear Supply (ECGS), saw a gap: an affordable, serviceable, and truly rugged 40-spline front axle package engineered as one cohesive system. “Every component—from the C-end to the lockout—was 100 % designed together as one unit,” Chase explains. “We didn’t bolt junkyard parts together; we built it all from scratch”.

Over 18 years of building custom axles informed the KP540’s development. ECGS runs large production batches—200+ spindles and hubs at a time—to reduce per-unit costs. This volume allows them to offer 40-spline strength at a price point accessible to more than just the top 5 percent of builders.

Why 40 Spline Axles?

As off-road builds grow in tire size, horsepower, and track width, the old standard of 35-spline shafts simply can’t keep up—both in sheer strength and in the lengths required for wide-track rigs. Stepping up to a true 40-spline design provides the extra torque and bending resistance modern applications demand, while also allowing manufacturers to produce longer, stiffer axles. In short, 40-spline is no longer a luxury upgrade but a baseline necessity for reliability, performance, and serviceability on today’s biggest and baddest rigs.

- Higher Torque Capacity: A 40-spline axle can handle approximately 12,000 ft-lbs of torque per axle, compared to about 9,300 ft-lbs for a 35-spline design—over 25 % more torque capacity before failure.

- Greater Shear & Bending Strength: By increasing the shaft diameter from 1.50″ (35-spline) to 1.710″ (40-spline), the cross-sectional area grows significantly, boosting resistance to bending and fatigue in shock-load scenarios.

- Improved Load Distribution: With more splines sharing the load, torque is spread across a larger number of contact points—reducing stress per spline and extending the service life of shafts and hubs.

- Durability in Longer Axles: As axle lengths increase (for wider track widths), 35-spline shafts become prone to deflection and fatigue. Manufacturers often refuse to produce 35-spline beyond certain lengths, opting instead for 40-spline to maintain rigidity over long spans.

- Optimized Strength-to-Weight: Although this offering can be heavier than other options, the system was engineered to be balanced, insuring weight and strength of all components are adequate. Delivering enhanced load capacity and rigidity while minimizing unnecessary mass—ideal for off-road performance builds.

Engineering Excellence, Part by Part

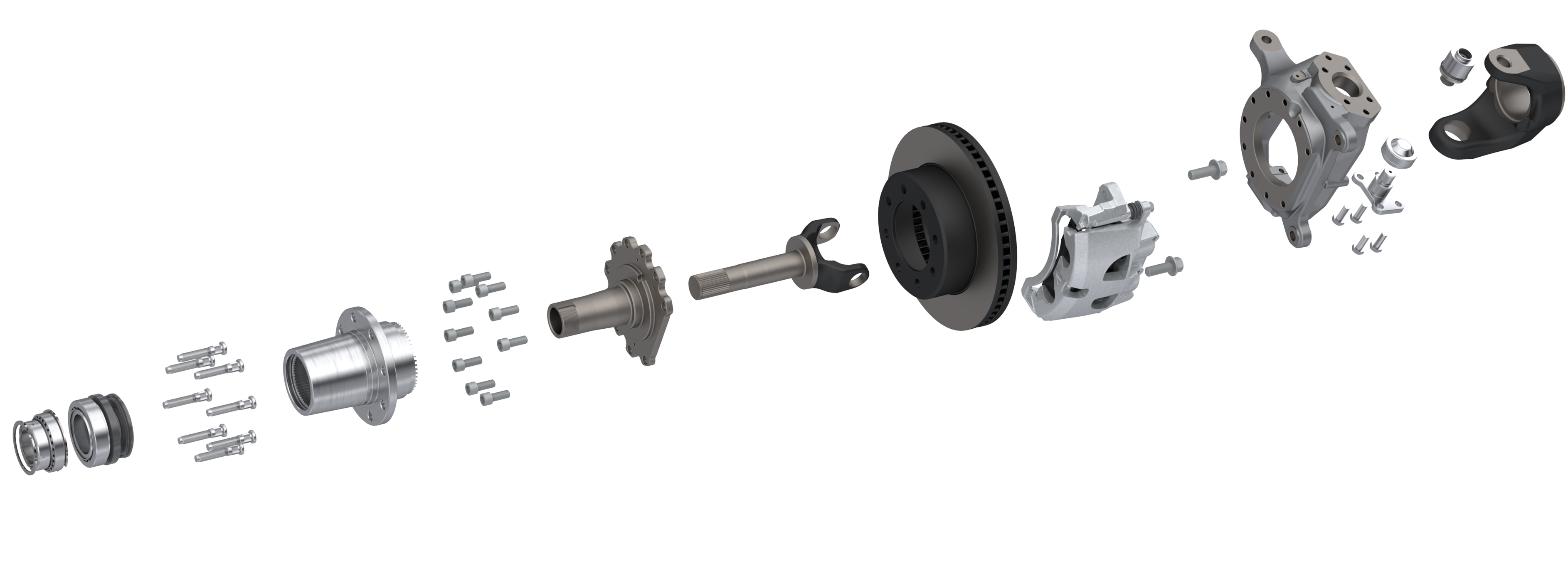

1. Massive Kingpin C-Ends & Forged Knuckles

The KP540 revives the old-school kingpin design for unrivaled strength. The massive Inner Cs and Knuckles are built to basically be indestructible. When Bushings and lower bearings wear, replacements cost mere dollars, not hundreds and are easily serviceable on the trail. The KP540 also shares bearings, races, seals, and spindle nuts with the Full Float 40 (FF40) rear spindle, so you only need to carry one set of spares for the whole vehicle.

Forged knuckles feature an optimized bolt-spread and stress-zone geometry, preventing cracking even under severe off-camber loads. The large opening in the middle allows for the massive 1550 U-Joints or even the RCV Big Bell CV.

2. Purpose-Built 40-Spline Spindle

A common practice to use 40 spline axles on a typical Kingpin spindle was to to bore out the spindle to fit the larger shaft. This drastically reduced the strength of the spindle causing premature bending or breaking. Instead of boring out a 35-spline spindle, ECGS increased both the OD and wall thickness on the KP540, yielding an 80,000 lb failure point—four times that of a stock one-ton spindle.

3. Oversized Timken Bearings & Wide Separation

ECGS chose much larger Timken bearings for the KP540 with up to 3× the load capacity of typical Dana 60 units, set further apart to distribute shock loads evenly.

Off-the-shelf availability means you can replace bearings at AutoZone, RockAuto, or directly through ECGS at anytime or anywhere.

4. Fully Forged Wheel Hubs & Serviceable Lockouts

Hubs are forged steel (no cast weak spots) yet retain a standard 8×6.5" bolt pattern—no custom wheels needed.

Choose between a simple 40-spline slug for dedicated off-road use or a manual lockout cap gives you the flexibility of on-road and off-road performance. ECGS offers the ONLY 40 spline lockout for front axles in the industry

5. Brake & U-Joint Flexibility

The KP540 accepts Dodge Ram 3500 factory calipers and rotors—no exotic brake parts required. Wilwood brake options are available for increased performance.

Traditional kingpin Dana 60 front axles commonly use the Spicer 1480-series U-joint (SPL55-4X) with a 3.00″ snap-ring spread, which is adequate for moderate off-road use but can become a weak link under high shock loads. In the KP540, we upgrade to the larger Spicer 1550 “Blue” U-joint (SPL70-4X) with a 3.78″ spread—delivering roughly 25 % more cross-sectional shear area and substantially higher torque and impact resistance for today’s 40″-plus tire, high-torque builds

U-joint options include the grease-able Dana Spicer 1550 “Blue” joint for street use, Branik’s 300 M/4340 no-needle bearings for hardcore shock loading. Big Bell RCVs is also an option for the ultimate in performance.

Real-World Validation

We teamed up with two respected voices in the off-road space to put the KP540 through its paces:

Ian Johnson (Big Tire Garage): “What you get is a full axle-end unit—inner C all the way to the lockout—engineered to be indestructible. No more patchwork.”

Nick (Rockstar Garage): “I’ve run other 40-spline setups, and I’ve bent spindles. The KP540 spindle won’t bend—it just doesn’t.”

What This Means for Your Build

- Confidence: Extreme-duty components that survive the nastiest hits.

- Convenience: Replace worn wear items in minutes, not hours.

- Cost Savings: High-volume engineering lowers your entry price for 40-spline performance.

- Customization: Tubes (3.5" or 4.0" OD), U-joints, shafts, bushings, and high-steer arms—build exactly what your rig needs.

Wrapping it Up

The KP540 isn’t just another aftermarket axle—it’s a reimagining of front-end strength and serviceability for today’s extreme off-road market. By engineering every piece as a unified package and leveraging production efficiencies, ECGS delivers a product that performs like a specialty unit but costs closer to a traditional axle rebuild.

Ready to stop worrying about your next broken spindle or seized hub? Discover the KP540 builder kit or pre-built front axle options and see why the future of front steering is here.