40 Spline Rear Builder Kit

- Forged chromoly spindles 4" and 3.5" tube

- Forged steel wheel hubs with axle shaft dowels – ABS compatible

- Forged cut to length 4340 chromoly axles

- Wheel bearing kit

- Spindle nut kit

- Spindle nut tool

Technical Discussion

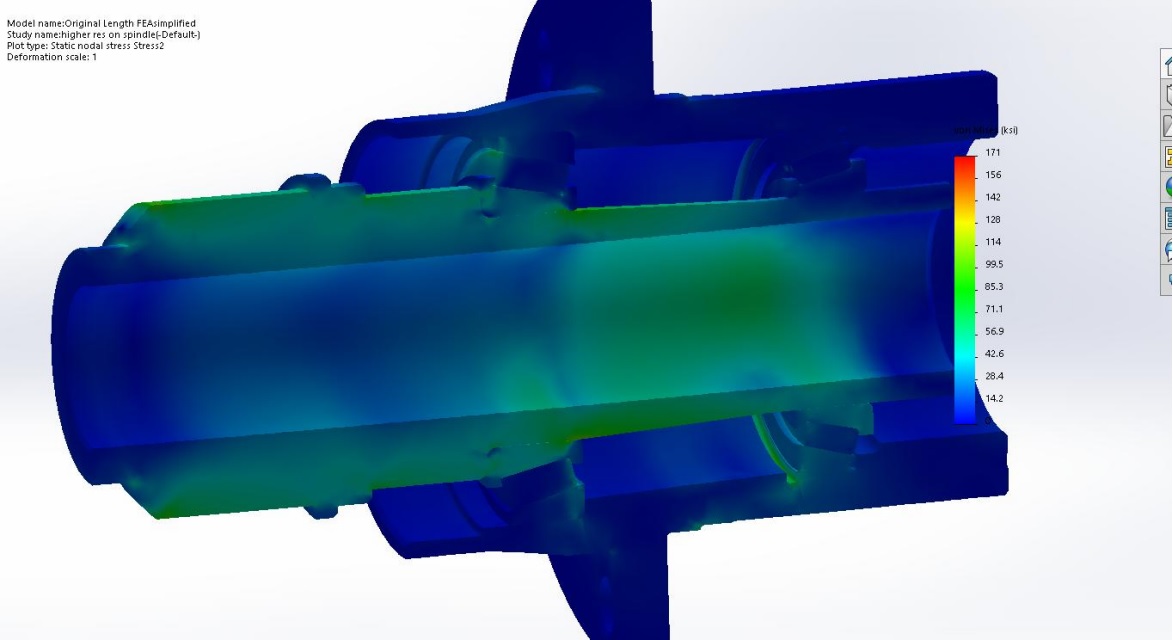

Spindle OD and Wall Thickness

Has been significantly Increased – This is the strongest spindle in production

- ECGS Spindle - 2.375" OD / .275 Wall thickness – 80,000 lb Yield Strength

- 14 Bolt Spindle- 2.00" OD / .200 Wall thickness – 20,000 lb Yield Strength

- ECGS Spindle OD at weld is either 3.5" or 4" for Smooth Transition to Tube

- 3.5" Spindle pilot – 2.625" IE 3.5" - 7/16's Wall. Turn for ½ Wall (3.5 x 3/8's wall adapters available)

- 4.0" Spindle pilot – 3.250" IE 4.0" - 3/8's Wall. Turn for ½ Wall (4.0" x ¼ wall adapters available)

Spindle Comparison Photo

(ECGS 40 spline vs GM14T Spindle w/ 35 spline shaft inside)

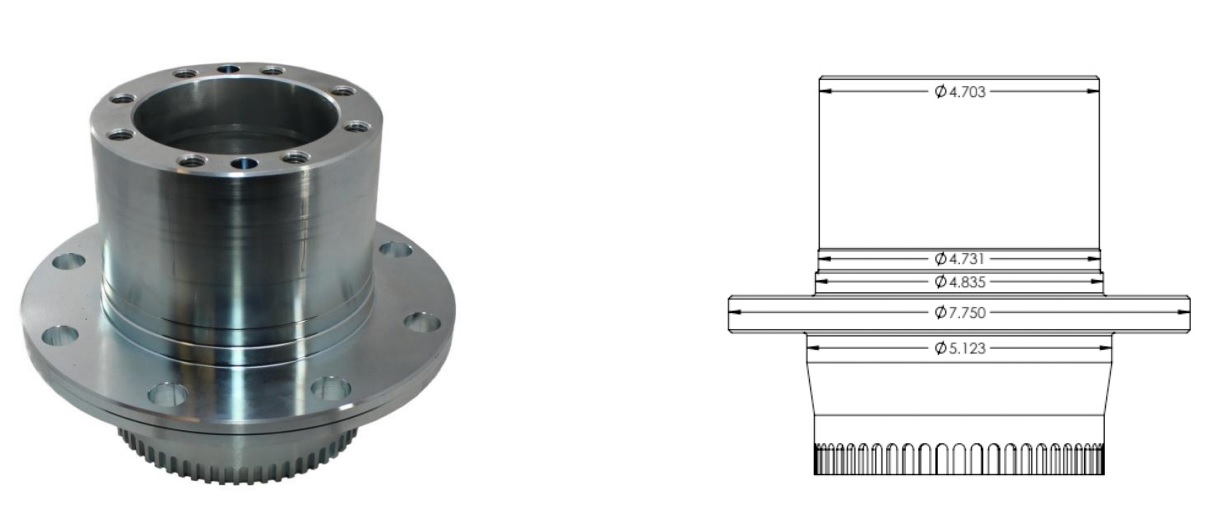

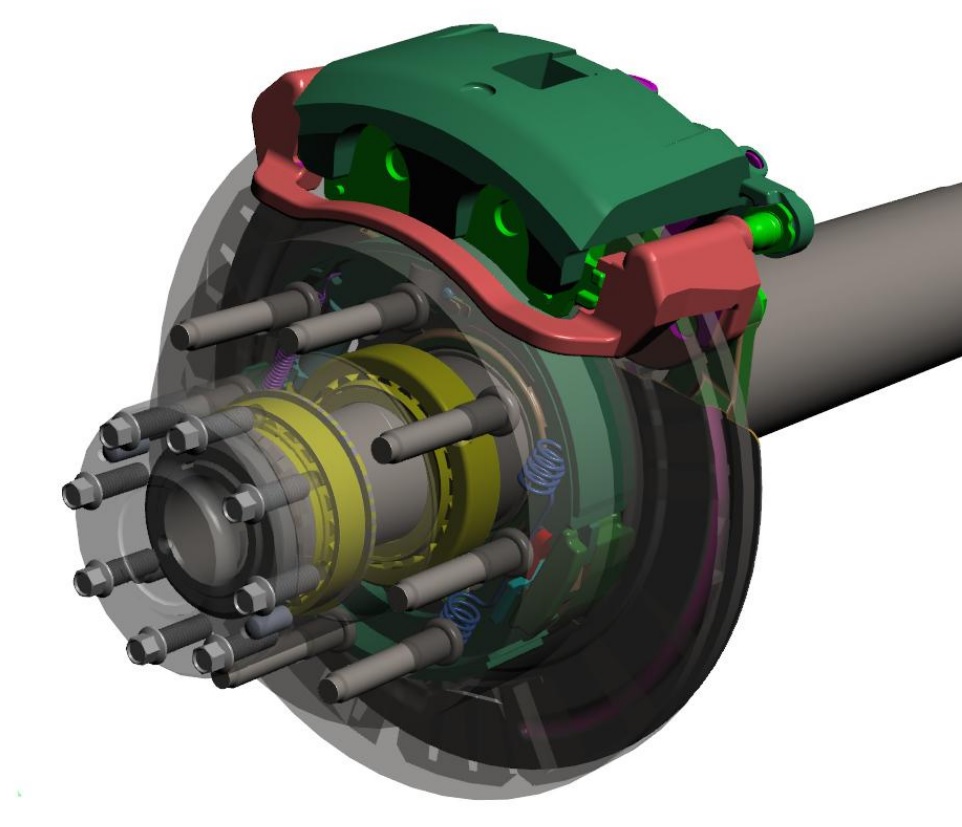

Wheel Hub Design

- ECGS Forged Steel 8x3.96" Pattern with Optional Dowels

- While designing, it was evident that if we were to increase the strength of the spindle, the hub became the weak link

- The only option we felt was to do a total redesign on hub and spindle in order to get the strength needed

- By properly spacing the wheel bearings to take stress off hubs, and transfer back into spindle we were able to achieve the 80K yield in both spindle and hub. Combining the use of superior alloys and forging in the manufacturing process, the hub is unmatched in strength to anything on the market.

- Wheel Hubs are available in 8x170 bolt pattern with 60 Tooth ABS Ring or 8 x 6.5 with 52 Tooth ABS ring.

- Both Wheel Hubs have small pilot holes with opposite wheel pattern to aid in a redrill for future use.

- Wheel hub is designed to take late Model Chevy 3500 hat style rotor with ebrake backing plate. The backside of the hub is also designed to take the universal GM14T disc brake kit popular for many Offroad applications, using the 80's Chevy front caliper and rotor. A high performance brake kit is in development.

FEA (Finite Element Analysis) Testing Photos During Design

Forged 4340 Chromo – Cut to Length Shafts

- Common 8x3.96" pattern with added dowels for increased shear strength

- Available in 37" / 41" – 6" spline (44.5" in production)

- Bolt in shafts to save cost on double spline shafts and drive flanges, including an off the shelf replacement provided one is broken

- Breaking Strength: 14,000lbs vs 9,000lbs on a 35 spline shaft

Summary Statement

We wanted to create a full float 40 spline kit that fits our customers' needs. It is no secret that 35 spline is no longer strong enough for 43" stickies and the punishment that higher horsepower motors are creating. It is also no secret that 14 bolt spindles are bending. We saw a need in the market for a larger shaft with a spindle and hub that would hold up to the abuse. Just boring a spindle is impossible, machining a factory style hub for a larger bearing to take a slightly larger spindle also does not work. Current hubs on the market will not allow for a large enough spindle and significantly weakens the hub. There are many variables that have to be considered: Outer Diameter, Wall thickness, spindle nut size, material, and geometry. All of these parameters impact the other.

ECGS also attempts to manufacture, build, and sell parts at a cost that the general market place can afford. To this end we invested heavily in tooling and in large production runs in order to bring the cost down. This is a 100% complete redesigned product offering, engineered to balance hub strength, spindle strength and bearing life. It is offered at an extremely competitive price point for a brand new turnkey full float wheel end kit. We believe this to be the least cost, strongest full float kit on the market, that has versatility for many applications from trail riding, over landing, and mining or equipment axles.

No expense was spared in material, heat treat or design. If you are considering a 40 spline upgrade. Consider your options and what matters.

Contact Information

For further assistance or inquiries, you can reach us at:

East Coast Gear Supply

566 Airport Rd

Louisburg, NC27549

Phone: 919-672-2705

Website: www.EastCoastGearSupply.com